In today’s era of environmental consciousness and industrial advancement, the spotlight shines brightly on sustainable solutions. Among these innovations stands the Carbon Dioxide (CO2) recovery plant, a groundbreaking technology offered by industry leader Solarkaz International (Pvt.) Ltd. In this blog, we explore the intricate workings and multifaceted benefits of CO2 recovery plants, detailing their applications and impact on industrial sustainability.

Introduction

CO2 recovery plants signify a leap forward in industrial sustainability, providing an eco-conscious alternative to traditional practices. With the working expertise, Solarkaz International introduces the pioneering SOKAZ CO2 recovery technology, engineered to optimize energy usage and operational efficiency while minimizing environmental footprint.

Key Functions and Working of CO2 Recovery Plants

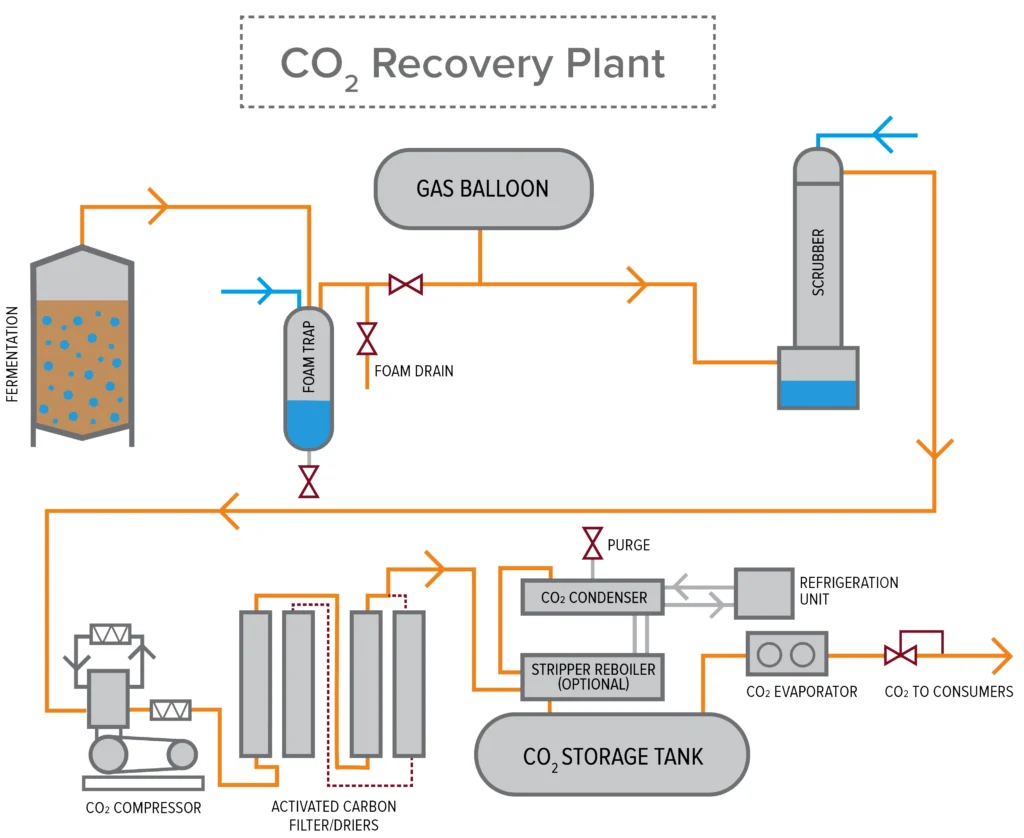

CO2 recovery plants play a pivotal role in modern industrial processes, offering a sustainable solution for capturing and utilizing carbon dioxide emissions. Through a meticulous process involving scrubbers, absorbers, heat exchangers, and gas vessels, CO2 is separated from other gases, ensuring purity and efficiency. These plants find applications across various industries seeking to minimize environmental impact and enhance operational efficiency.

Reliable CO2 Source

Industries ranging from beverage carbonation to enhanced oil recovery benefit from the dependable and cost-effective CO2 supplied by recovery plants.

Energy Efficiency

Industrial facilities seeking to minimize energy usage and reduce operational costs leverage the energy-efficient design of CO2 recovery plants.

Optimized Solvent Consumption

Sectors such as food processing and wastewater treatment benefit from reduced solvent consumption offered by CO2 recovery plants.

Oxygen Resistance

Industrial settings with fluctuating oxygen levels in flue gas emissions rely on the resilience of CO2 recovery plants for consistent performance.

Varied Capacities

From small-scale operations to large industrial facilities, CO2 recovery plants cater to varying production demands with customizable capacity options.

Maximum CO2 Extraction

Industries aiming for high CO2 recovery rates, such as greenhouse gas mitigation projects and carbon capture initiatives, rely on the superior extraction capabilities of recovery plants.

Operational Process of CO2 Recovery Plant

Stack gases containing CO2 enter the scrubbers. CO2 is absorbed from the stack gases by a MEA (Monoethanolamine) solution in the absorber. The CO2 -rich MEA solution is pumped to the desorber. In the desorber, the MEA solution is heated, causing the CO2 to be released from the solution. The purified CO2 is then cooled and transferred to storage tanks. The regenerated MEA solution returns to the absorber to capture more CO2, initiating a continuous cycle. This process employs water as a coolant and a specially formulated MEA solution as the absorbent. Solarkaz’s system is designed to be energy efficient and utilizes stainless steel process towers and pumps for a long lifespan.

Where it's used

CO2 recovery plants are utilized across a spectrum of industries including beverage production, oil and gas exploration, food processing, wastewater treatment, greenhouse gas mitigation projects, and carbon capture initiatives.

Benefits for Customers

Environmental Conservation

CO2 recovery plants play a crucial role in reducing greenhouse gas emissions, aligning with sustainability objectives and regulatory standards. This solution offers versatility, applicable also to waste heat recovery chambers. By capturing CO2 emissions in these systems, industries can simultaneously reduce environmental impact while optimizing energy efficiency through the reuse of waste heat.

Cost Savings

By providing a reliable and efficient CO2 source, these plants deliver significant cost savings over conventional methods, contributing to long-term financial viability.

Operational Efficiency

Solarkaz’s CO2 recovery technology enhances industrial processes, improving productivity and operational performance while reducing environmental impact.

Long-Term Reliability

Utilizing durable materials and advanced engineering, CO2 recovery plants ensure longevity and consistent performance, guaranteeing years of service and reliability.

Solarkaz International’s Smart Solution

We introduces a smart economic solution with CO2 recovery plants.

Let's delve into the details

To produce just 1 kg of CO2, you’d typically require approximately 2 kg of steam at 4 bar and 140°C, alongside a mere 0.25 kWh of electrical power. Picture this with a genset capable of producing 800 kg/h of steam, you can effortlessly yield around 250 kg/h of CO2.

So, what's on our Wishlist?

It’s straightforward – we need essential details like exhaust flow rate, exhaust temperature, and either stack gases composition or fuel composition from your end.

What's in it for you?

Our cutting-edge CO2 recovery plants, ranging from 300 kg/hr to 1000 kg/hr capacity, complete with a convenient filling station.

And here's the clincher

It’s all backed by our rock-solid guarantee, thoroughly verified, and meticulously quality-assured with certifications. At Solarkaz International, we pride ourselves on delivering top-notch solutions, ensuring sustainability across industries worldwide.

Conclusion

In conclusion, CO2 recovery plants stand out as essential pillars of sustainable industrial practices, paving the way for environmentally conscious and efficient operations. Solarkaz International’s unwavering dedication to innovation and environmental responsibility underscores the critical role of these technologies in sculpting a sustainable future for global industries. Embracing CO2 recovery plants not only amplifies operational efficiency but also cultivates a cleaner and more sustainable industrial ecosystem for generations to come. At Solarkaz International, we take immense pride in the recognition and appreciation our services and products receive from our valued customers.

Together, let us continue to pave the way towards a brighter, more sustainable tomorrow, where every action is a step towards a cleaner and greener future. Contact us for understanding more about our offerings and solutions.