Biomass which is the renewable energy source of organic material is now an emerging source of fuel used worldwide for power boilers.

Advantages of Biomass As Fuel

Biomass can be used for several industrial and domestic purposes as well as is useful as boiler fuel. Biomass is being used as an effective alternative to traditional coal, petroleum coke or oil, and gas fuels.

Biomass has a low impact on the environment compared to conventional fossil fuels. This type of energy production has a limited long-term effect on the environment because the carbon in biomass is part of the natural carbon cycle, while the carbon in fossil fuels is not, and does not permanently adds carbon to the environment as compared to the burning of conventional fuels.

Some of the advantages of Biomass fuel in boilers are as follows:

- Environmentally friendly, non-polluting, and non-hazardous fuel

- Produces low Carbon footprints

- Widely available

- Produced and degraded easily as compared to the availability of oil and gas reserves which are being depleted at the faster pace

- Less expensive.

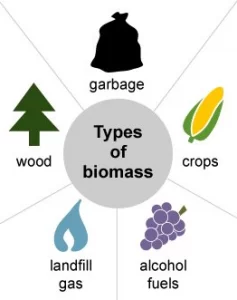

Types of Biomass Fuels

Biomass fuel is produced from a wide range of materials. These burning fuels include wood, agricultural residues, animal manure, and organic wastes from households and industries.

Want to Know About Biomass Boilers?

Biomass boilers are very similar to gas boilers but use several types of organic compounds like Biomass Pellet, wood, Waste Cloth, Rice Husk, Peanut Shell Bagasse, Bamboo Chip Mustard Stalk, Wood Chip, cotton seed, corn cob, Cotton Stalk, etc. as fuel sources.

The conventional life cycle of working of biomass boilers employs:

- The sources of fuel are first converted to pellets.

- These pellets are then transported to the industries for feeding into the biomass boilers.

- The pellets are fed into the automatic feed hopper of the biomass boiler which stores pellets and feeds them into the boiler when needed.

- After combustion of the fuel, the fuel ashes are accumulated into the ashtray from where they are removed as per the instructions of the boiler manufacturer.

Wrong Perception

Some people have the idea that biomass boilers are labor intensive, due to the traditional perception of how they work. In the past, people thought that they needed to fill up the boiler every day and clear it out occasionally to ensure that it worked properly.

This is no longer the case with modern biomass boilers, as they can provide clean, efficient, and technological solutions for the needs of the modern world. But still safety and prevention of boilers is necessary in terms of its use, because if the boilers are not properly maintained and cleaned there exists a chance of boiler eruption which could be catastrophic.

This is no longer the case with modern boilers and biomass boilers, as they can provide clean, efficient, and technological solutions for the needs of the modern world.

Being Futuristic

Nowadays, biomass boilers are engineered in a way to reduce labor while providing a fully automated system of feeding, bed functioning, exhaust gas emissions, and fan-forced or natural draft mechanism as per international standards and provide space flexibility for various fuels within the feeding chamber of the boiler.

Solarkaz International has expertise in manufacturing biomass boilers which could provide all of the above features with a fully automatic control system and additional safety and reliability. Our aim is to provide a quality product to our clients at economical prices.

Looking for the Biomass Boilers? Contact us to get FREE enquiry about Biomass Boilers.