INTRODUCTION

In the world of managing heat and improving energy efficiency, heat exchangers are essential tools. They are crucial for various applications, from industrial operations to residential heating and cooling systems. These devices enable the transfer of heat between fluids, ensuring that processes run smoothly while conserving energy. In this blog, we’ll take an in-depth look at different types of heat exchangers, examining how they work and where they are used.

Different Types of Heat Exchangers:

Some of the types of the Heat Exchangers are as follows:

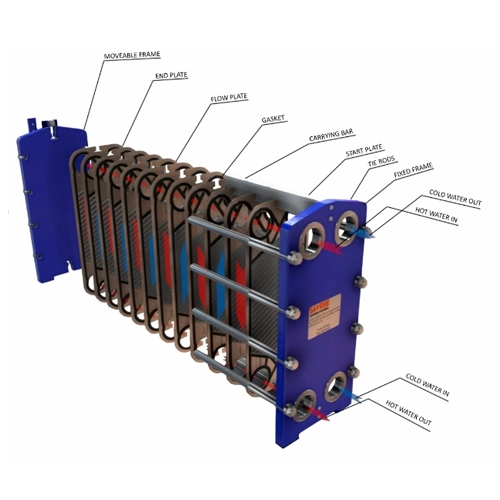

1) Plate Heat Exchangers:

Maximizing Efficiency Through Compact Design

Thin Plate Configuration:

Plate heat exchangers consist of multiple thin plates aligned parallel to each other

Fluid Channels:

These plates form channels through which fluids flow, allowing for efficient heat transfer between them.

Compact Design:

heat exchangers are known for their compact design, which minimizes space requirements and allows for installation in tight spaces.

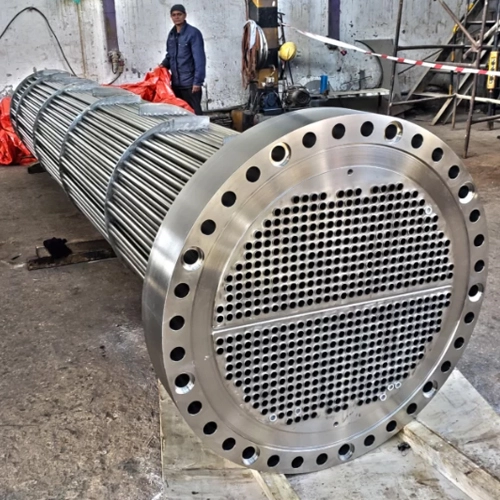

2) Shell and Tube Heat Exchangers: Versatile and Reliable Solutions

Tube-and-Shell Configuration:

Shell and tube heat exchangers are versatile, capable of handling a wide range of operating conditions and fluid types.

Fluid Circulation:

One fluid flows through the tubes, while the second fluid circulates around the exterior of the tubes within the shell.

Versatility:

Shell and tube heat exchangers are versatile, capable of handling a wide range of operating conditions and fluid types.

Durability:

They are known for their robust construction, making them durable and suitable for demanding industrial environments .

High Thermal Performance:

This design promotes efficient heat transfer between the two fluid streams, ensuring high thermal performance.

Industry Applications:

Shell and tube heat exchangers find extensive use in industries such as petrochemical, where they are employed for heat transfer in processes like oil refining, and chemical production also used in textile sectors.

3) Finned Tube Heat Exchangers: Enhancing Surface Area for Improved Efficiency

Tube with Fins:

Finned tube heat exchangers consist of tubes with extended surfaces, or fins, attached to their outer surfaces.

Increased Surface Area:

The addition of fins significantly increases the surface area available for heat transfer compared to plain tubes.

Enhanced Efficiency:

The larger surface area facilitates more efficient heat transfer between the fluids, resulting in improved overall efficiency of the heat exchanger.

Common Applications:

Finned tube heat exchangers are widely used in various industries and applications, including air conditioning, heating systems such as boilers and furnaces and Aerospace.

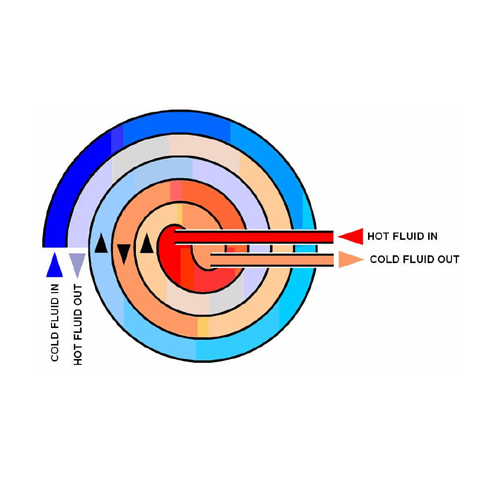

4) Spiral Heat Exchangers: Optimal Heat Transfer in a Compact Package

Spiral Configuration:

Spiral heat exchangers are characterized by their unique design, consisting of flat plates coiled around a central core, forming a spiral shape.

Turbulent Flow Promotion:

The spiral configuration promotes turbulent flow within the heat exchanger, enhancing heat transfer efficiency compared to laminar flow.

Suitability for High-Viscosity Fluids:

Due to their enhanced turbulence, spiral heat exchangers are particularly well-suited for handling high-viscosity fluids that would typically experience challenges in conventional heat exchangers.

Wastewater Treatment Applications:

Wastewater Treatment Applications: Spiral heat exchangers find extensive use in wastewater treatment processes, where they effectively transfer heat between wastewater streams and facilitate the treatment of industrial effluents.

Wide Industrial Applications:

Spiral heat exchangers are employed across various industries, including chemical processing, pulp and paper, and food and beverage, where they play a crucial role in thermal management and process optimization.

Solarkaz International: Your Partner in Heat Exchange Solutions

At Solarkaz International, we specialize in providing cutting-edge heat exchange solutions tailored to meet your specific requirements. With years of experience and expertise, we offer a comprehensive range of heat exchangers designed to optimize thermal performance, minimize energy consumption, and enhance operational efficiency. Whether you’re seeking plate heat exchangers for industrial applications, our team is committed to delivering innovative solutions that exceed your expectations. Our track record speaks for itself, as evidenced by the utmost satisfaction of our esteemed clientele with our exceptional performance and superior product offerings .

Conclusion:

In the ever-evolving field of thermal engineering, heat exchangers stand out as essential components for optimizing heat transfer and promoting energy efficiency. Through a comprehensive exploration of the diverse range of heat exchanger types and their wide-ranging applications, we gain valuable insight into their pivotal role across numerous industries. With Solarkaz International by your side as a reliable partner, you can leverage cutting-edge heat exchange solutions to propel sustainable growth and realize your operational objectives with confidence.