INTRODUCTION

INSPECTION AND ASSESSMENT

- Trained professionals conduct a thorough assessment to evaluate the tank’s current condition.

- Identifying signs of corrosion, leakage, structural damage, or any issues that could compromise safety and integrity. A meticulous inspection sets the foundation for targeted rehabilitation efforts.

SAFETY MEASURES

- Securing the work area for personnel safety.

- Ensuring that all personnel involved are adequately trained in handling LPG.

- Adherence to strict safety protocols is non-negotiable, considering the potentially hazardous nature of the material being handled.

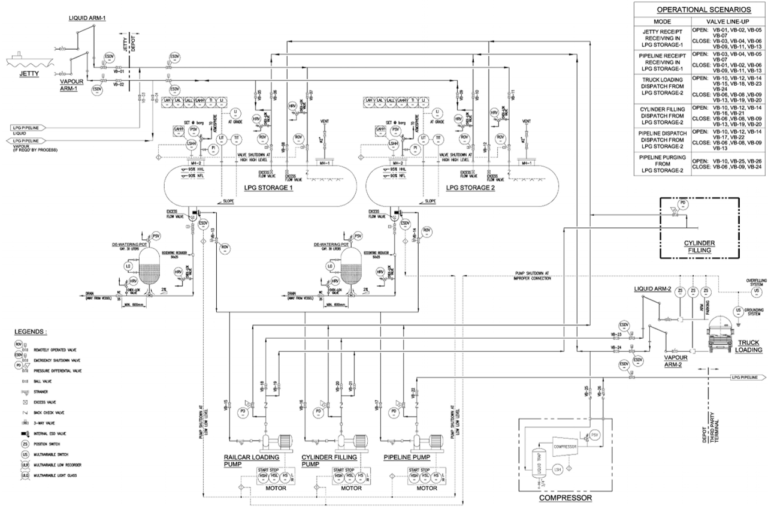

EMPTYING AND PURGING

- Safely emptied of any remaining gas.

- A purging process is initiated to remove residual gas, making the tanks safe for maintenance activities.

- Mitigating potential risks associated with gas handling.

CLEANING AND SURFACE PREPARATION

- Surface preparation, involving the removal of old coatings if necessary.

- Clean and prepared surfaces facilitate thorough inspections and enhance the efficacy of subsequent repair and protection measures.

CORROSION PROTECTION

- The application of corrosion-resistant coatings or the installation of sacrificial anodes.

- The goal is to extend the lifespan of the tank and ensure its continued safe operation.

CORROSION PROTECTION

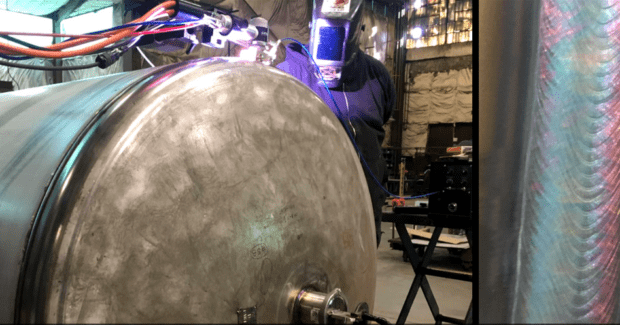

Addressing structural issues is a critical component of the rehabilitation process. This involves:

- Welding repairs for cracks or the replacement of damaged components.

- The focus is always given on restoring the tank’s structural integrity to meet stringent safety standards.

LEAK DETECTION AND REPAIR

- Thorough leak detection tests are conducted to identify and repair any points of leakage.

- Seals, valves, and connections are scrutinized to ensure they are in good condition.

INSTRUMENTATION AND SAFETY SYSTEMS

- Checking and calibrating instrumentation and safety systems.

- Outdated safety features are updated or replaced to meet current industry standards. This step is crucial in maintaining the overall safety and efficiency of the storage facility.

INSTRUMENTATION AND SAFETY SYSTEMS

- Checking and calibrating instrumentation and safety systems.

- Outdated safety features are updated or replaced to meet current industry standards. This step is crucial in maintaining the overall safety and efficiency of the storage facility.

INSTRUMENTATION AND SAFETY SYSTEMS

Stringent testing procedures includes Pressure/Vacuum tests, which are conducted to ensure the tanks meet safety and operational standards. Obtaining necessary certifications and approvals from regulatory authorities is imperative to validate the rehabilitation efforts and compliance with industry regulations

DOCUMENTATION

Detailed documentation of all rehabilitation activities, inspections, and tests is maintained. This documentation serves as a record for regulatory compliance and provides valuable insights for future reference. A comprehensive record enhances transparency and accountability in the rehabilitation process.

CONCLUSION

In the realm of LPG storage tank rehabilitation, prioritizing safety, precision, and adherence to industry standards is essential for sustainable energy infrastructure. This comprehensive guide underscores the critical role of qualified professionals in ensuring the continued efficiency and safety of LPG storage facilities.

As a standout player in this arena, Solarkaz International emerges as a dedicated partner committed to excellence. Beyond being a service provider, Solarkaz International embodies a commitment to surpassing industry standards. Clients with Solarkaz International attest to the unwavering commitment to safety, expertise, and excellence, ensuring a resilient and efficient energy infrastructure.

Choosing Solarkaz International means aligning with a partner deeply invested in providing the services with longevity and reliability of energy infrastructure. Join us in shaping a future where energy security thrives under the meticulous care and expertise offered by Solarkaz International, setting a new standard for the industry. For inquiries and opportunities, reach out to Solarkaz International — your trusted partner for innovative and secure energy solutions.