Pressure vessels, as defined by ASME Boiler and Pressure Vessel Code (BPVC) Section VIII, are containers for the containment of pressure, either internal or external. The application of heat from a direct or indirect source because of a process, or any combination of the two, can create this pressure.

What are ASME codes?

ASME is abbreviated as “American Society of Mechanical Engineers”. The ASME Code is the construction standard for pressure vessels and contains standards that must be followed, prohibitions that must be avoided, and mandatory and non-mandatory advice for pressure vessel materials, design, fabrication, examination, inspection, testing, and certification.

Types of Pressure Vessels As Per ASME Code

Pressure vessels are organized into five types:

Type I

All-metal construction, generally steel.

Type II

Mostly metal with some fiber overwrap in the hoop direction, mostly steel or aluminum with a glass fiber composite; the metal vessel and composite materials share about equal structural loading.

Type III

Metal liner with a full composite overwrap, generally aluminum, with a carbon fiber composite; the composite materials carry the structural loads.

Type IV

An all-composite construction, polymer — typically polyamide (PA) or high-density polyethene (HDPE) liner with carbon fiber or hybrid carbon/glass fiber composite; the composite materials carry all the structural loads.

Type V

Liner-less, all-composite construction.

Types of Pressure Vessels According to Shape

1. Spherical Pressure Vessels

High-pressure liquids are best stored in this specific kind of pressure vessel. Because the forces are evenly distributed over its surface, both internally and externally, a spherical construction is exceptionally sturdy. As a result, all weak places are eliminated, but it is also true that making them can be far more expensive than making cylindrical ones.

The fact that spherical pressure vessels have a smaller surface area per unit of volume than any other shape is a major advantage. Accordingly, compared to cylindrical storage vessels, the quantity of heat that is transferred to liquid within the sphere from warmer surroundings will be significantly smaller.

Spherical vessels make up the majority of LNG (Liquid Natural Gas) and LPG (Liquid Petroleum Gas) tanks. They are also used to hold butane, propane, ammonia, oxygen, hydrogen, and nitrogen.

Advantages

A spherical shell pressure vessel would be more cost-effective when you need to create storage for a large volume of pressurized liquid or gas, which means you need a massive pressure vessel.

Disadvantage

The fabrication cost of spherical shell pressure vessels is higher than that of cylindrical pressure vessels, and only big vessels can justify this higher cost.

2. Cylindrical Pressure Vessels

Because cylindrical vessels are less expensive to create than spheres. Cylindrical Vessels are frequently utilized for storage. However, because of the weak spot at either end, cylinders are not as powerful as spheres.

By fitting hemispherical or rounded ends, this vulnerability is lessened. Storage pressure can be comparable to that of a sphere if the entire cylinder is constructed from thicker material than a comparable spherical tank of similar capacity.

Types of Cylindrical Pressure Vessels According to Head

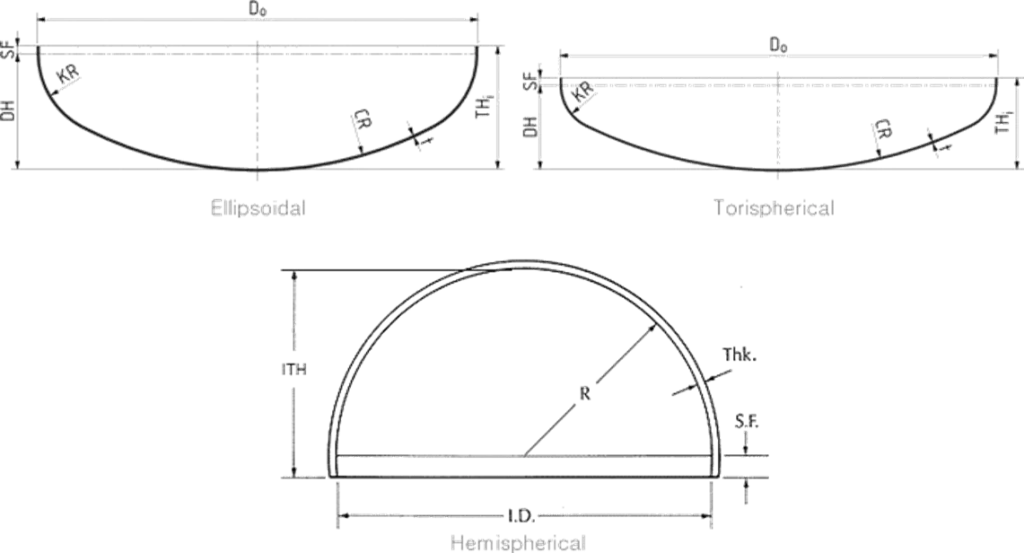

Three different ASME pressure vessel end heads are ellipsoidal, hemispherical, and tori spherical.

✔️ Ellipsoidal Head

The 2:1 elliptical head is another name for this. Because the height of the head is just one-fourth its diameter, it has a more practical shape. Between the major and minor axes, its radius changes.

✔️ Hemispherical Head

Because the pressure inside the vessel is distributed evenly throughout the surface of the head, a spherical is the best shape for a head. The head’s radius (R) is the same as the cylindrical portion of the vessel’s radius.

✔️ Torispherical head

The size of the dish on these heads, which has a defined radius (CR) and varies depending on the type of torispherical head, is fixed. The knuckle is the point where the cylinder and the dish meet. The knuckle is shaped like a torus.

Do We Fabricate Pressure Vessels?

Solarkaz International is an ASME certified company, with ASME “U Stamp” and “S Stamp” and ISO certifications as well. We fabricate pressure vessels for various industries, including Beverages, Pharmaceuticals, Water & Wastewater, Oil & Gas, Food and health care etc.

Discover the importance of water treatment and the role of pressure vessels in ensuring the safety and efficiency of industrial equipment. Solarkaz International offers comprehensive solutions, from fabricating pressure vessels for storage to providing water treatment plants and chemicals for optimal performance and protection.

Looking for pressure vessel solutions? Contact us to know more about the Pressure Vessels.